i-Master Microwave Digestion System

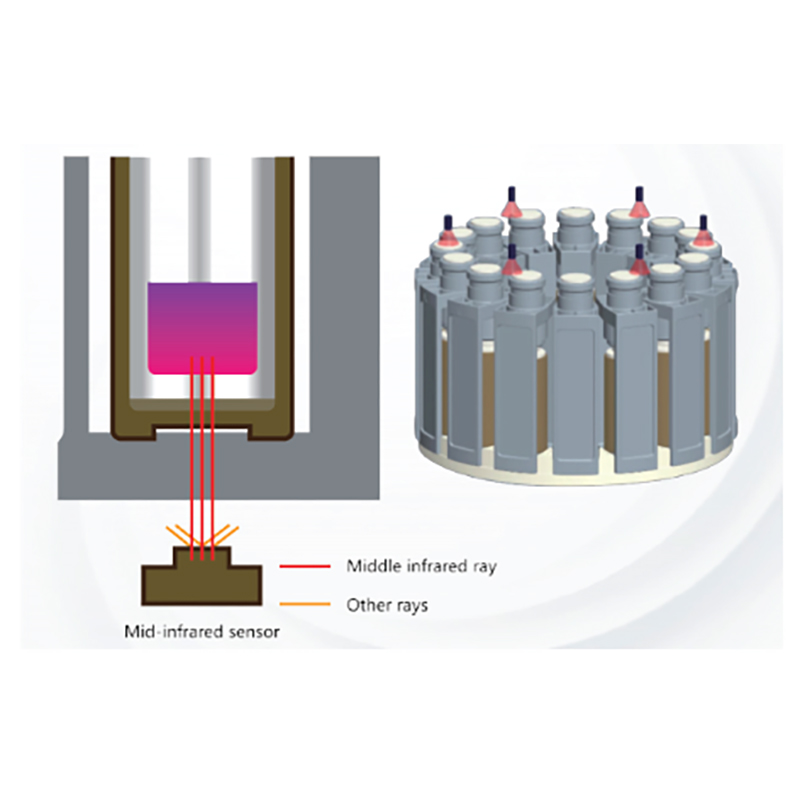

Microwave digestion technology is to use microwave penetration and activation to heat reagents and samples in sealed vessels, which can increase pressure and temperature, thus greatly improve reaction rate.

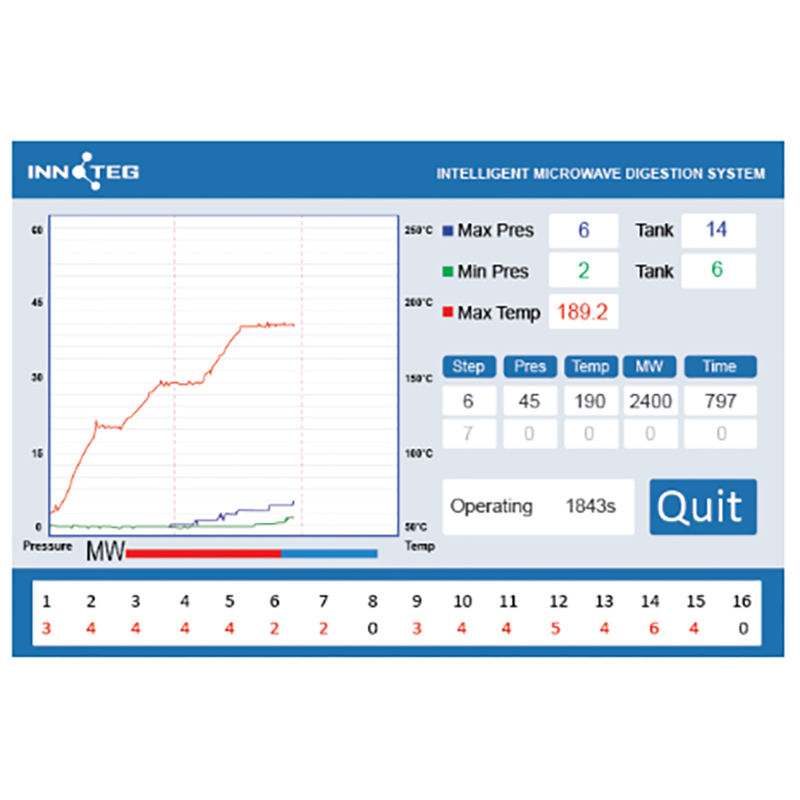

INNOTEG i-Master can monitor temperature and pressure of all samples in vessels by the advanced non-contact technology to enhance safety of digestion process. It also ensure uniformity which cannot be guaranteed when using single point temperature and pressure measuring in conventional microwave digestion systems.