Description

Features and Benefits

- Measurement range: 1 – 10,000 µm

- Results in compliance with ISO 9276-6

- Highly reproducible measurements

- A high-speed CCD camera

- Powerful software eases your work

- Automatic sample stage with high position accuracy

- 24 different particle size and shape parameters

- A key part of surface cleanliness measurements

Why Image Analysis Method?

Easy

Capture an image of particles, identify particles, then measure their size and shape. Every step of image analysis is easy and clear.

Shape analysis

Based on a direct view of particles, it is possible to analyze not only the size of particles, but also their shape.

Seeing is believing

The image analysis method determines the size and shape of every individual particle and then sums it up to form a statistic. Details of particle size or shape distribution can be accurately provided.

Why Static Image Analysis Method?

Clear vision

In static image analyzers, precision microscopes and high-resolution cameras are specialized for high – quality particle images.

Undersized particle sensitivity

The static image analysis method is sensitive to undersized particles; it is even possible to estimate the size of undersized particles.

Small sample volume

The static image analysis method requires a small volume of samples. A few drops of emulsions or a few micrograms of powders are enough to do a measurement.

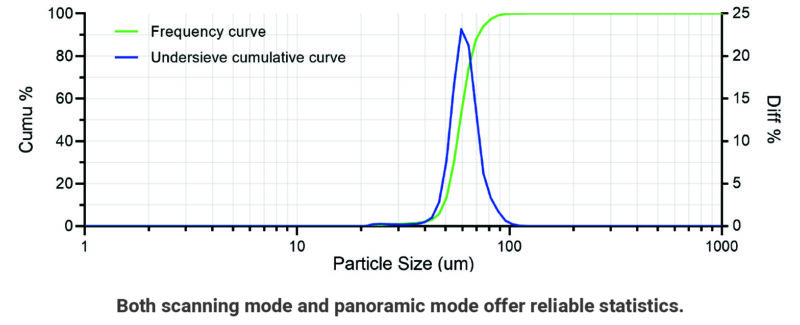

Efficient Scanning Mode and Limit – breaking Panoramic Mode

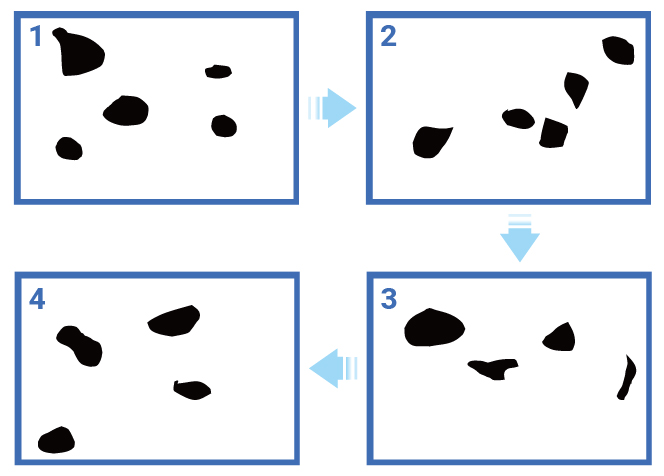

Scanning Mode

The workflow of the BeVision M1 scanning mode is to capture an image first, then analyze the image while moving the stage, capture the next image once the stage has reached a new position, and repeat.

The BeVision software will display real-time results during the scanning process. The scanning mode is widely welcomed in different industries with its efficiency and reliability.

Efficient and reliable scanning mode

Compared with the manual test, the automatic scanning process improves the test efficiency, doing the image capturing and stage moving simultaneously pushes the efficiency to the next level. The efficient scanning mode analyzes many particles in one test, thus strengthening the statistical significance of the result.

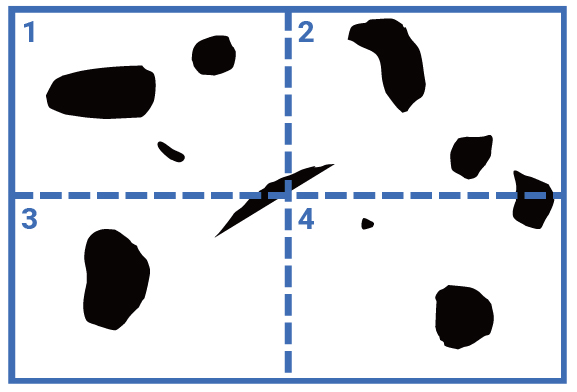

Panoramic Mode

The panoramic mode is to stitch separate images into a panorama before analysis.

With a panorama, it is easy to measure the total number of particles in the region and the size and shape of every particle, even if the particle is an oversized one. The accurate particle number is of vital importance to different industries, e.g., the automotive industry and the pharmaceutical industry.

A combination of macro vision with micro details

Panoramas produced by the BeVision M1 records all particles dispersed in a millimeter-level region and keeps their shape details. A clear panorama helps to accurately count particles in the macro-region and analyze the size and shape of particles, without any leftovers.

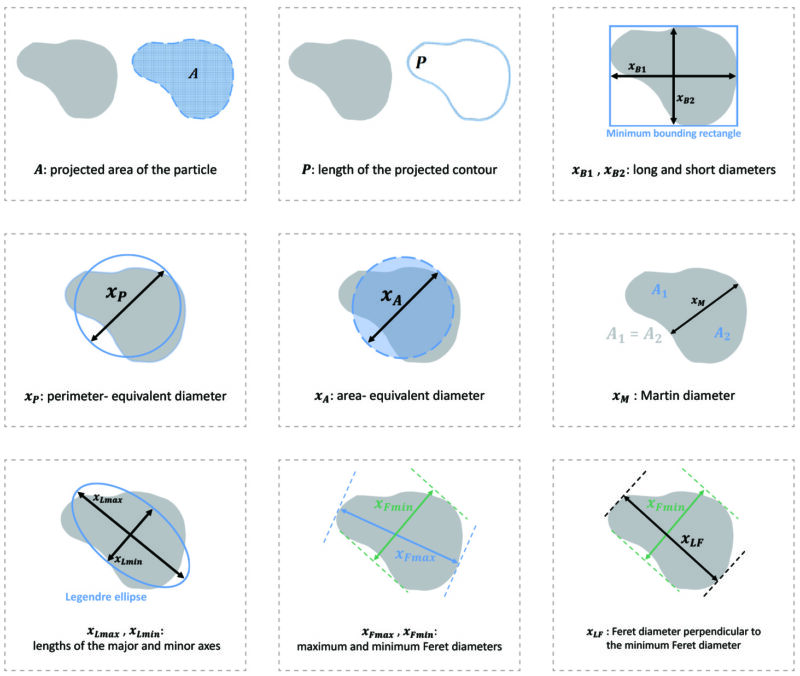

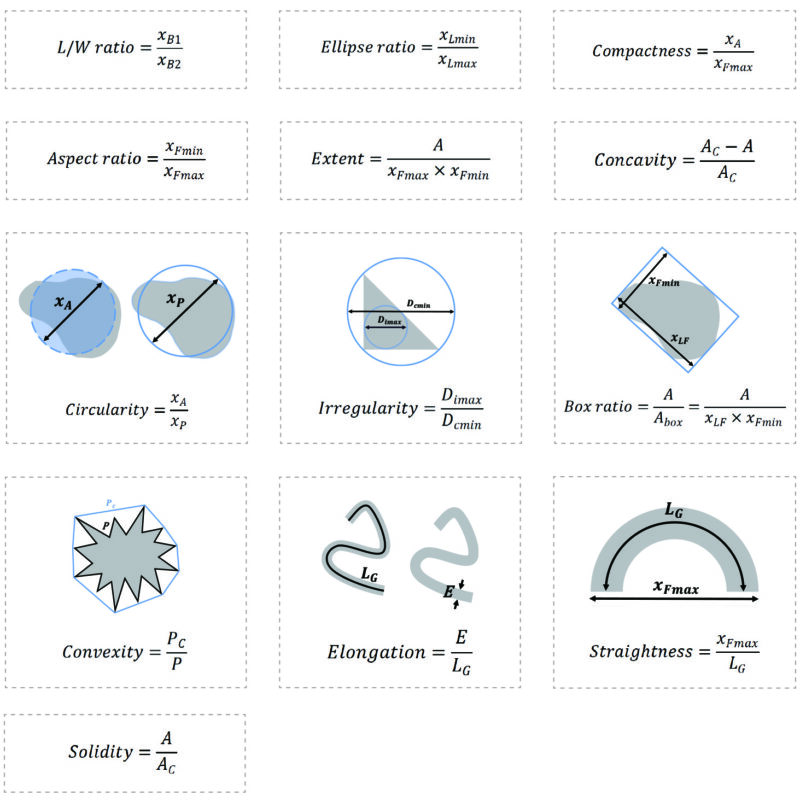

Particle Size and Shape Parameters:

Size parameters

Equivalent diameters: area-equivalent diameter、perimeter-equivalent diameter; Feret diameters: maximum and minimum Feret diameters, XLF (“length”)

Martin diameters: maximum and minimum Martin diameters; Legendre ellipse: major and minor axe

Shape parameters

Size difference in 2 directions: aspect ratio、L/W ratio、ellipse ratio; Round-likeness and rectangle-likeness: Circularity、irregularity、compactness、extent、box ratio

Contour concavity: Concavity、convexity、solidity; For elongated particles: Elongation、straightness

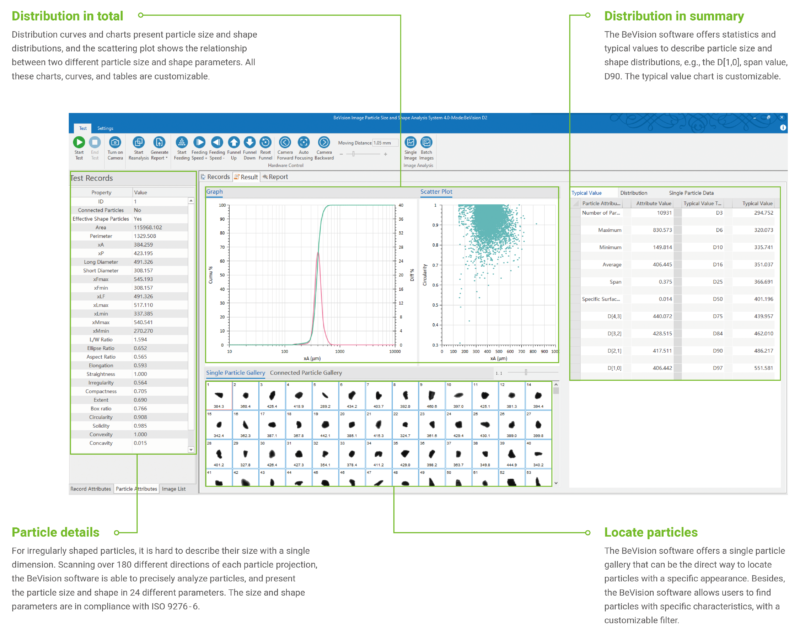

BeVision Software: Visualized Insights for You:

Typical Applications: