Description

Laboratory glassware washer feature:

Humanized Operating System

- The man-machine interface features a 7-inch color LCD touchscreen(WD-60 is 4.3 inch), enabling intuitive touch operation within the visual field for convenient operation. It includes pressure sensing, making it well-suited for complex operating environments.

- The PLC programmable micro-computer operating system ensures stable and reliable performance. It is designed to be anti-magnetic and resistant to breakdowns.

Standardized Cleaning

- Dual Peristaltic Pumps:Disinfection effectiveness mainly depends on the correct performance of the washing phases and the neutralization of the treated material. Creatrust washers come equipped with two peristaltic pumps: one dedicated to dispensing the alkaline detergent during the cleaning phase and the other for dispensing the acid neutralizer during the neutralization phase.

- By controlling the cleaning process and monitoring key cleaning parameters through automatic program flow control, the automation and standardization of vessel cleaning can be achieved;

- Equipped with two water inlets controlled by electromagnetic valves, users have the option to select between tap water and purified water during the wash and rinse phases

- The 360° spray mechanism ensures comprehensive internal and external cleaning of the container, eliminating dead spots and ensuring optimal cleaning effectiveness.

- The pure water inlet features an integrated booster pump, enabling direct suction of purified water without the need for an external booster

- Consistency is maintained across different batches, as well as within each batch, ensuring the cleaning effect at every point remains uniform

- Enables traceability management of cleaning data for enhanced record-keeping and accountability.

Filter System

Equipped with dual stainless steel filters to safeguard the recirculation and drainage systems. These filters can be effortlessly removed for cleaning. Additional filters are installed on all incoming water lines and air intakes to ensure debris is pumped out effectively.

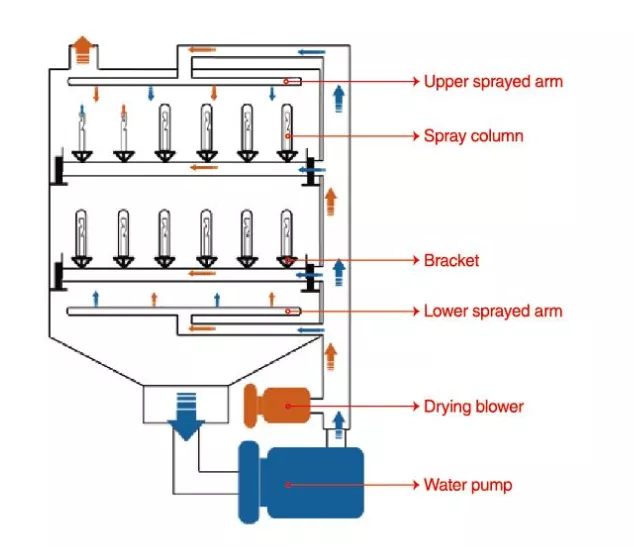

Drying System

- The forced-air “Drying System”Comprised of an efficient hot air generator and a powerful fan, the system is directly managed by the programmer, enabling control over both operating time and temperature parameters. The microprocessor PLC system ensures intelligent management of the drying circuit, automatically adjusting the fan speed (thereby reducing power consumption) based on the temperature measured in the washing chamber. The efficient hot air temperature can be adjusted up to 120, enhancing the washing, rinsing, and sanitizing of glassware, as well as enabling faster drying.

- Patented TWINs System for DryingThe patented TWINs system integrates hot air with cleaning pipes, ensuring hot air reaches every corner with a 360-degree radius and no dead ends. It achieves synchronous drying of utensils and the circulation pipeline, preventing long-term moisture that can lead to bacterial growth within the pipeline.

Washing & Drying Cycle

Water Conductivity Monitoring (Optional Accessories)

Water Conductivity Monitoring: The sensor gauges the concentration of dissolved inorganics, such as calcium and ferrous ions, in the tank water. This provides validation of water cleanliness, hardness, and rinsing thoroughness, while also confirming the proper dispensing of detergent, rinse aid, and purified water.